5 Tips to Prevent Cross Contamination During Cleaning

What is cross contamination?

How can it be prevented from a cleaning stand point?

Here are 5 tips to best prevent cross contamination during the cleaning process.

What is Cross Contamination?

Cross contamination is the act of moving pathogens or soils to areas that could be exposed to humans which could potentially harm the individual(s) involved. In the case of cleaning – cross contamination can happen when cleaning around a toilet, followed by cleaning the restroom counter top with the same cloth. The next 5 tips will help prevent cross contamination during the cleaning process in very simple ways.

1: Use of Microfiber Cleaning Utensils

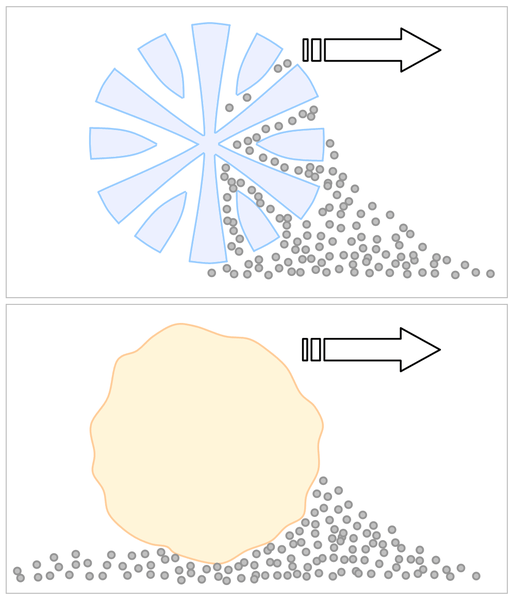

Microfiber is a material that is made of synthetic fibers that attract dirt, bacteria, and other pathogens like a magnet. Microfiber tools are made to attract and capture up to 99% of dirt, bacteria and other pathogens, while cotton fiber tools are made to attract 33% – basically moving bacteria from surface to surface. Therefore, the use of microfiber cloths, mops, and other microfiber tools allow for the removal of bacteria, dirt and allergens, because microfiber is designed to attract and hold these elements. The image on the right simulates the microfiber structure under a microscope in the top image. The bottom image is a regular cotton structure which ultimately pushes dirt & bacteria around, rather than collecting it.

Such microfiber tools include:

2: Implementation of a Color Coding System

When several people are responsible for the cleaning, it can become very difficult and almost impossible to ensure everyone knows which microfiber cloth is used for the restroom and which one is used for the lunch room! Color coding is a great way to ensure that everyone on the team knows which ones to use for the toilets and which to use for the counter top. Just be sure that everyone knows the color system which leads us into the next tip- training.

3: Training and More Training

The essential and most obvious tip for preventing cross contamination is training- making sure everyone on the team is aware of the system that is in place, such as color coding. However, the less obvious tip is to always continue training and supervising. Supervisors should keep a cautious eye that the system in place is continually followed on a daily basis by the crew members.

4: Separate and Clean Tools, Chemicals and Equipment

Along with tips 2 and 3, keeping the tools, chemicals and equipment is equally as important as the cleaning system in place to prevent cross contamination. Ensure the janitor’s closet is clean and well organized, i.e. to prevent the bathroom mop from laying next to or on top of the kitchen mop. Also, certain chemicals are used for specific applications and therefore should not be mixed or confused with an application that the chemical is not designed for.

5: Eliminate Outdated Cleaning Methods and Tools

Technology has advanced the impact of today’s new cleaning products, providing greater cleaning results and greater health results for those who clean and those who occupy facilities. We all know the green movement is no longer a movement, rather a new standard, but still, many cleaning practices used are still outdated.

Outdated practices can be replaced easily with healthy and effective cleaning practices that deploy new technology: